As supply chain networks become more intricate, it is only fitting that there is a solution to help purchasers and their suppliers manage their interactions. For this reason, many firms look to a supplier portal, sometimes known as a vendor portal, as their tool of choice.

A supplier portal is an online platform where companies can collaborate and communicate with their third-party suppliers. Since teams often engage with several suppliers, the supplier portal effectively becomes the simplest way for businesses to enter information, submit documents, track orders and raise concerns with future engagements. The benefit of doing this is that buying organizations can now identify patterns and reduce other redundancies in the supply chain.

As a procurement tool, these portals are often available for businesses as a software-as-a-service solution (SaaS), meaning it is hosted and maintained by an external provider with transaction-based pricing. The benefit is that the purchaser does not need to purchase lots of hardware or infrastructure to run the system, although some licenses or subscriptions may be required to access the tool.

With this definition in mind, the next logical question many businesses have is, what can a supplier portal do? And how should my team be using one?

Supplier Portal Capabilities

To grasp the essence of a supplier portal, it's crucial to recognize the array of business and procurement processes it can manage for effective supplier management.

A supplier portal facilitates:

1. Vendor Onboarding2. Electronic Invoice Submission

3. Invoice and Payment Inquiry, encompassing payment history and details

4. Payment Disputes - submission and tracking

5. Procurement, post-sourcing and solicitations

6. Supply Chain Management

7. Dynamic Discounting

How to Use Your Supplier Portal

Looking at a high-level, many teams have distilled the benefits of a supplier portal to their ability to eliminate manual, paper-based processes. By doing so, these same businesses have reported an increase in efficiency in passing documents and interactions between the purchaser and supplier.

The five examples below delve into more details about what this means for your team.

1. Automate Document Creation, Transfer and Storage

Consider an example to understand one of the main uses of a supplier portal. Today, many companies will undergo a process of document exchange in which a purchase order (PO) is generated within their own Enterprise Resource Planning (ERP) system. Following the creation, a PDF version of the PO is often downloaded to be printed or emailed to their suppliers. Upon receiving the purchase order, the vendor is likely to make their own digital version, with the intent to record it in their own ERP system. As you likely noticed, these steps involve repeated efforts, which result in more time-consuming tasks.

By incorporating these otherwise separate steps, teams have found opportunities for automation, such as through the automatic generation of a Purchase Order (PO) from the details found in one’s Purchase Requisition (PR). Additionally, duplicated steps such as the buyer and supplier digitizing their documents to be input into their ERP system are eliminated so that the details of a PO may only be created and uploaded once. Moreover, an ERP system can create a cXML file uploaded to a user’s portal, which can be transferred automatically from system to system, being made available in the vendor’s ERP system, without the need for scanning or OCR. These same benefits can later be seen in the resulting documents that come with a PO being turned into products received and paid for by the supplier with the click of a button.

2. Create a Self-Service Environment for Onboarding and Managing Supplier Accounts

As your team begins the process of onboarding a new backup supplier or any other vendor for your roster, several setup steps will likely need to be completed. To name one example, consider that this process involves the setup of master data for the supplier in your own ERP system. While the onus would traditionally be on your team to input this data into your system, the existence of a supplier portal flips the switch, so it is now up to the supplier to onboard themselves in a self-service alternative. The secondary benefit to this setup is that if at any point the supplier needs to update their data, they can do so without needing to contact a member of your team.

In addition to simplifying some of the lengthy processes in vendor onboarding, the portal interface enables teams to sign into an account and make inquiries with the supplier directly. Consider that the traditional alternative is making these inquiries by phone or email, two communication methods that may lose context with details not being readily available to the rest of the team.

In this sense, engaging with and managing a supplier account becomes possible via a single portal. Teams can log in and view account information, history of purchase orders, past invoices, etc., in the same place where they are contacting a member of the supplier's team. Since all this information is in one place, teams can see updates and any previous messages made between parties as well.

3. Streamline Candidate Prequalification

Tired of sifting through outdated databases to vet potential clients? Simplify the process by automating it through a supplier portal. Suppliers can fill out a tailored RFI-style questionnaire within the registration tool, serving as a prequalification survey when joining your company. These surveys are scored and directed to the relevant buyer within your organization, saving time and lightening the workload for everyone involved.

4. Leave Notifications to the Technology

With the number of approvals going back and forth between buyer and supplier, it is no secret that a series of notifications and reminders are needed at different stages of the process. While a purchasing team member may normally be tasked with sending out an email reminder to notify or remind the suppliers of this approval, this step can be automated so the supplier can be reminded to proceed with the next actions anytime a delay is noted.

Although notifications may look different depending on how the portal is built, the benefit for end users is that, in theory, nobody has the less-than-fun-job of following up until a process is complete.

4. Achieve Savings Through Shorter Payment Cycles with Dynamic Discounting

One of the key benefits of the supplier portal is the advantages it provides teams in standardization. With a supplier portal, many otherwise lengthy, paper-based processes can be automated with their digital counterparts. The result is that payment terms for discounts can be achieved since the processes are shorter. Therefore, with a supplier portal, many businesses on the buyer side have been able to reap savings and suppliers have been able to increase cash flow that would be more costly otherwise.

5. Create a Record for Traceability

With a single location to store all relevant supplier data, your team begins to build an auditable trail of all POs, goods received, and any issues raised along the way. The benefit is that at any point in time, a member of the purchasing organization can view events over time for a given document, with details including the actions taken, the time, the IP address (or other identifying details) of the user carrying out the event. Additionally, all these documents (PR, PO, Goods Receipt, Invoices) are linked together in an end-to-end business process rather than as isolated events.

Now, in the event of a misunderstanding, your team will have the ability to pinpoint where things went wrong and hopefully reach a solution before the problem escalates.

6. Enhance Supplier Oversight and Reporting

With a supplier portal, you gain the ability to monitor suppliers based on commodity and diversity categories, offering insight into your company's advancement towards internal objectives. Tailored reports generated from portal data ensure you stay aligned with spending targets and pinpoint potential risks, such as dependence on a single supplier.

Implementing a Supplier Portal of Your Own

When it comes to selecting the ideal supplier portal for your business, it's essential to consider functionality tailored to your business size, type, needs, and budget. The perfect supplier portal should enhance efficiency, thereby reducing operating costs. Seek scalability to ensure the portal can accommodate your business's growth trajectory.

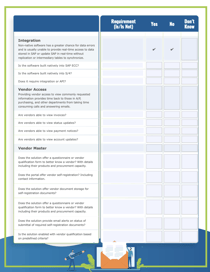

Craft a checklist outlining crucial aspects of a supplier portal that align with your company's budget constraints.

During the evaluation and selection process of supplier portal software, distinguish between desirable features on a wishlist and essential capabilities for a must-have list. Additionally, consult reviews and ratings to gauge the performance of software offerings with supplier portals.

To help with your comparison, download our free vendor comparison checklist linked below.